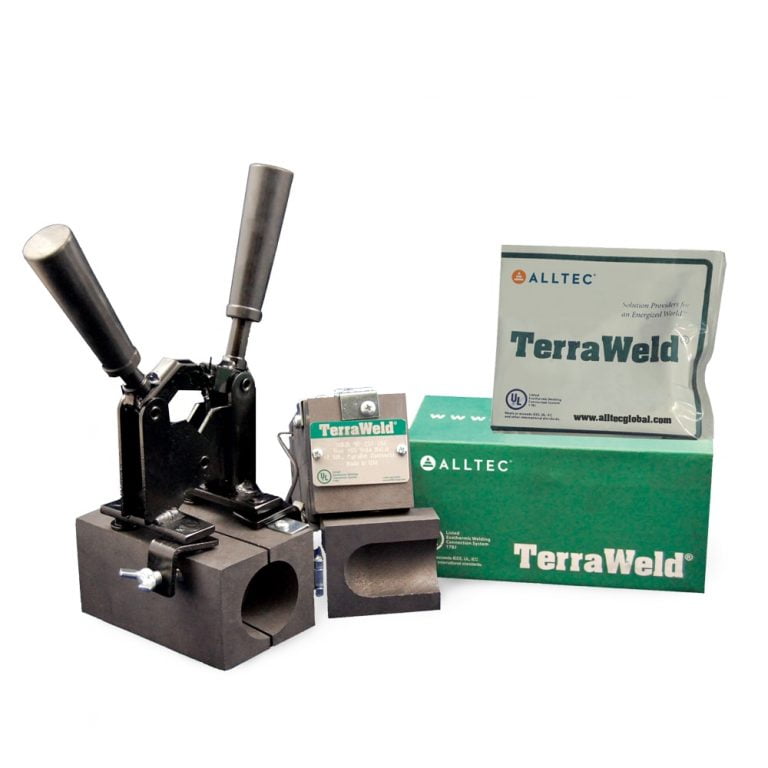

The TerraWeld® Exothermic Welding System

Provides a Superior Solution via permanent Molecular-Bonding.

TerraWeld® – Features

- Maintains current carrying capacity exceeding that of the conductors in the system

(necessary for all lightning protection and grounding systems)

- Only connections that will not loosen or increase resistance over the lifetime of the installation.

- Most preferred connection method especially for belowgrade Connections.

TerraWeld® – Benefits

- TerraWeld®’s system resistance, impedance andampacity meet all challenges and deliver assurance for your company.

- Pressure type connections are susceptible to variation,aging, corrosion and failure—not TerraWeld®.

- Provides higher fusing capacity than conductors to whichthey’re bonded.

- Complies with all regulations for functionality and safety.

- Provides performance superior to all existing surface-to surface mechanical retention connectors.

Compliances

TerraWeld® is distributed internationally and meets or

exceeds the standards for the following:

- UL 467

- IEEE 80, 837 and 1100

- NEC Article 250

- IEC 62305

TerraWeld® Exothermic Welding System

TYPICAL APPLICATIONS

- Cable-to-cable splices, tee connection, cross run connection,parallel connections, etc.

- Wire grid-to-ground rod, cable-to rod.steel sheets and pipes and rod-to-rod splices.

- Tap conductor-to vertical/horizontal pipe, flat surface, or plate.

- Through conductor-to vertical /horizontal pipe, flat surface or plate.

- Bus bar & wire-to-rail connections.

- Solid or stranded cable, metal tape, re-bar, and terminal lug connections.

COMPATIBLE WITH:

- Copper

- Steel

- Columbium

- Bronze

- Iron

- Copper-clad steel

- Stainless steel

- Monel

- Niobium

- Brass

- Silicon bronze®